wire edm machine is an electro process

The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task. Wire EDM is a type of CNC machining technology capable of unique results.

Rule Based Dfm Analysis For Electric Discharge Machining Wikipedia

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques.

. EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal conductive part. Tips For Wire EDM. The operation method varies from machine to machine.

Conventional EDM cannot produce narrower angles or more complex patterns while wire-cut EDM can be performed. The arbor is the drive shaft of the machine which rotates at high speeds in order to force metal into the cutting area. EDM is similar to processes such as laser cutting.

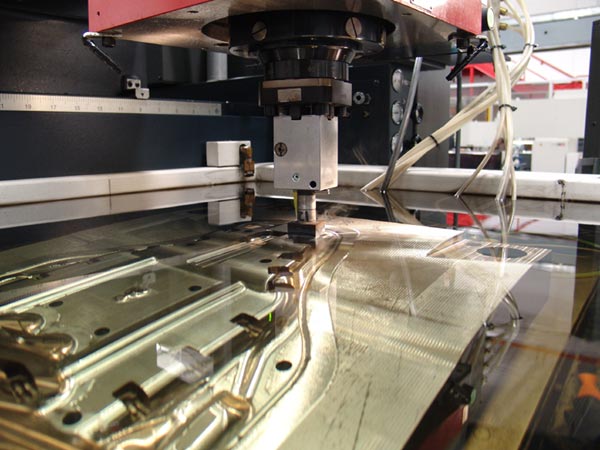

The wire EDM machine is capable of cutting a metal thickness of about 0004 inches. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust. It cuts using the same mechanism as die-sinking however the die is replaced with a very fine electrically charged wire.

Ad Full suite of CNC machining services including the latest in wire EDM machining. Both the workpiece and the wire are submerged in the dielectric fluid. The electrical discharge machining EDM process as we know it today started with the observations of Joseph Preistly in 1770.

However engineers rely on it to create parts that are impossible to machine. In wire electrical discharge machining WEDM also known as wire-cut EDM and wire cutting a thin single-strand metal. Wire EDM is the most precise cutting process by the help of wire EDM we can get up to two Micron of precisionI hope you will lik.

Wire EDM in process Wire EDM machine. It is not the most popular CNC machining process available. What Is EDM Machining EDM is a machining process that uses electrical currents to cut metal.

It is often used for the production of metal parts with complex geometry. They have high alignment accuracy and are very convenient for electrode wire positioning. Usually they are non-ferrous and.

Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive. On some machines it is possible to adjust the angle of the wire to create angled faces or tapered parts.

An edm machine contains three main components. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Sinker EDM machines are ideal for hardened materials and complex part details that are difficult to machine by other methods.

So as to generate a high temperature to melt or vaporize the metal forming a slit thereby cutting parts. Introduction Electro Discharge Machining EDM is an electro-thermal non-traditional machining process where electrical energy is used to generate electrical spark and. Wire Edm Machine Is An Electro Process.

This method remove materials by using a controlled and fast frequent electrical charges. Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. Tradenamesalternative names for Wire EDM.

EDM wire cutting titanium processing is based on the electro corrosion phenomenon during the pulse discharge between the electrode and the workpiece each pulse discharge will generate a large amount of heat so that the local metal near the discharge point instantaneously melted and vaporized and throw the molten and vaporized metal away from. The dielectric fluid acts as a insulator between the electrodes and. Electro Discharge Wire Cutting EDWC.

At a certain thickness the wire EDM wire only evaporates the metal thereby eliminating. EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics. A Brief Bit of EDM History.

This is a wire EDM machine. The nature of the Wire EDM process means that you can achieve shapes and structures that are next to impossible with other CNC methods and can give you incredible results. What is Wire EDM.

A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece. A Makino wire EDM machine reduces wire consumption by up to 50 less over competitive models. For quality parts delivered on time choose Xometry cnc machining services.

The Electro Erosion process is often used in the production of blanking and casting dies. This technique removes the conductive material using spark erosion which is the primary principle of the edm process. Wire EDM machining Electrical Discharge Machining is an electro thermal production process in which a thin single-strand metal wire in conjunction with de-ionized water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks.

Ad For creating more complex geometries w high accuracy. The process is applicable only for electrical conductive materials such as metals. Wire EDM otherwise known as wire erosion is commonly used to produce extrusion dies.

EDM Working Principle Electrical discharge machines work on the principle of material removal using a series of electric Spark discharges occurring between the electrode tool and the workpiece. The theory on which Electrical Discharge Machining EDM is based is centuries old. This is also known as electro-discharge erosion.

Some machines have an adjustable bed which also allows the workpiece to be angled creating an angled cut. Both of these should be electrically conductive. Electrical Discharge Machining Used on hard metals works with.

He noticed that electrical discharges had removed material from the electrodes in his experiments. This process allows the wire to cut through metal by the use of heat from electrical sparks. Introduction of Electro Erosion.

Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape. Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method. The machine tool is processed according to the numerical control program.

A metallic wire usually brass or copper has high voltage electrical discharges passed through it that allows it to cut through the entire thickness of the material. The EDM process uses a charged shaped electrode in a submerged bath of dielectric fluid to machine conductive materials. A potential difference is created between the electrode tool and workpiece.

40 Years of Quality Value and Service. The so-called wire EDM as its literal meaning is the use of moving metal wire as the electrode wire by pulse electric spark discharge between the electrode wire and the work-piece. A more precise cutting process allows for more complex cuts.

EDM can cut intricate contours or cavities in pre-hardened. In the 1940s two Soviet researchers the Lazarenkos developed a. This machining method is comparable to a cheese cutter making a two-dimensional cut in a three-dimensional part.

The Wire EDM process is a subtractive manufacturing process. An arbor the electrode holder and the dielectric fluid. In wire edm the conductive materials are machined with a series of electrical discharges sparks that are produced between an accurately positioned moving wire the electrode and the workpiece.

WEDM programming is the focus of the entire process. Ad Maintain Your EDMs Performance With High Quality Wire Consumables.

Wire Cut Edm Process 2 Download Scientific Diagram

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Wire Electric Discharge Machining Wire Edm Youtube

Mas 865 How To Make Something That Makes Almost Anything

Block Diagram Of Wire Edm Machine Source Technological Manual Of Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

Wire Edm Find Suppliers Processes Material

What Is Wire Edm Electrical Discharge Machining Xact

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Edm Machining Sprutcam 14 All Lang User Manual

A Japax Ldm 50 Wire Edm Machine B Schematic Diagram Of Wire Edm Process Download Scientific Diagram

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control

What Is Wire Edm Electrical Discharge Machining Xact

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube